Description

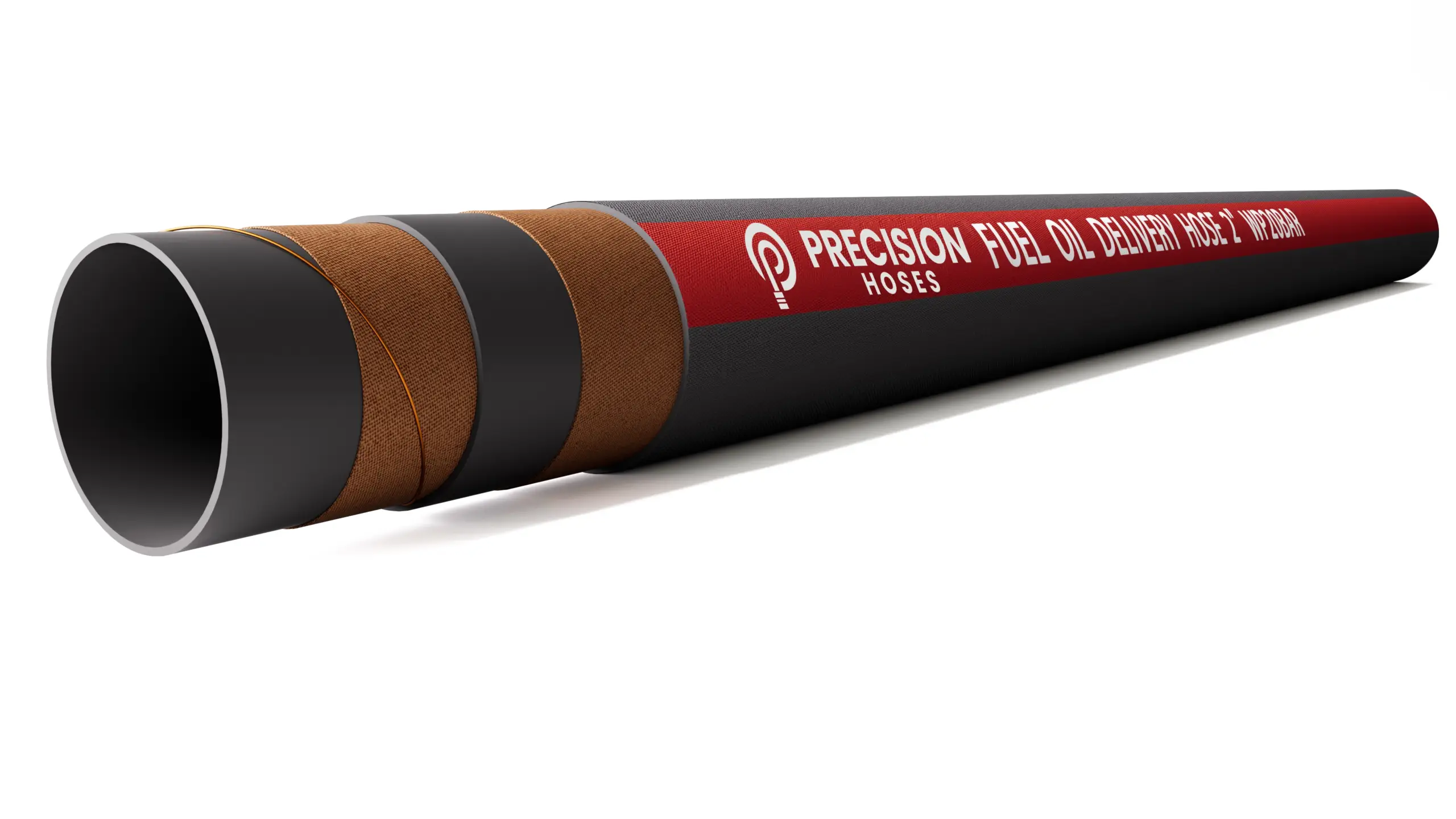

The Diesel/Gasoline Suction and Discharge Hose is specifically designed for handling the suction and discharge of petroleum-based products such as diesel, gasoline, oil, and other fuel blends. This versatile and durable hose is suitable for use in a wide range of applications, including fuel transfer, loading and unloading of tankers, and in industrial or marine environments. Its construction ensures safety, flexibility, and high performance in handling volatile fuels.

1. Construction

- Inner Tube: The inner tube is made from nitrile rubber (NBR), which is highly resistant to the corrosive and degrading effects of diesel, gasoline, and other petroleum products. The smooth inner surface provides excellent flow characteristics, reducing turbulence and ensuring efficient fuel transfer.

- Reinforcement: The hose is reinforced with high-tensile synthetic textile plies and a steel wire helix, providing the hose with superior strength and flexibility. The steel wire helix prevents the hose from collapsing during suction operations and maintains the hose’s shape under vacuum pressure.

- Outer Cover: The outer cover is constructed from weather-resistant synthetic rubber, which is highly resistant to abrasion, weathering, oil, and ozone exposure. This ensures long-lasting performance in harsh outdoor environments.

2. Standard Sizes

- Inner Diameter: Typically available in sizes ranging from 1 inch (25mm) to 6 inches (150mm), offering flexibility to accommodate different flow rates and volumes.

- Length: Standard lengths range from 10 to 50 meters, with custom lengths available for specific applications.

3. Working Pressure

- The hose is designed for both suction and discharge operations with medium to high working pressure, typically rated between 10 to 20 bars (145 to 290 psi), depending on hose diameter and construction.

4. Vacuum Rating

- The hose is capable of handling full vacuum service, with a vacuum rating of up to 29 inches of mercury (Hg), making it ideal for fuel suction tasks in tankers, refineries, and fuel depots.

5. Temperature Range

- The hose is suitable for a wide temperature range, from -20°C to 80°C (-4°F to 176°F), allowing it to perform well in various climates and weather conditions.

6. Performance Characteristics

- Fuel Compatibility: The nitrile rubber inner tube is designed to handle various petroleum products such as diesel, gasoline, oil, and other refined fuels, ensuring safety and reliability.

- Suction and Discharge Capability: Reinforced with a steel wire helix, the hose can handle both suction and discharge operations without collapsing or kinking, making it versatile for different fuel transfer tasks.

- Durability: The weather-resistant outer cover ensures the hose can withstand tough environments, such as exposure to the elements, rough handling, and abrasive surfaces.

- Flexibility: The steel wire helix and textile plies provide flexibility and prevent the hose from deforming, allowing for easy handling and installation, even in confined spaces.

- Oil and Ozone Resistance: The hose’s outer cover resists the effects of oil spills and ozone exposure, ensuring a longer service life in outdoor and industrial applications.

7. Applications

- Suitable for fuel transfer in industrial, marine, and transportation sectors.

- Commonly used for the loading and unloading of fuel tankers, fuel depots, and oil refineries.

- Ideal for mobile refueling operations, such as fueling heavy machinery, trucks, or agricultural equipment.

- Used in marine environments for fuel handling on docks or ships, ensuring safe and efficient fuel transfer.

8. End Fittings

- Compatible with a wide range of fittings, including camlock couplings, threaded fittings, or quick-connect couplings, allowing for secure, leak-proof connections to tanks, pumps, or fueling equipment.

9. Certifications

The manufacturer of the products supplied by Precision Hoses Pty Ltd is certified under the ISO 9001:2008 Quality Management System, ensuring a consistent commitment to quality. Additionally, the manufacturer’s products have achieved key industry certifications, including the BV Certificate, CE Certificate, ECM Certificate, and CCS Certificate, awarded in 2010. These certifications highlight the exceptional standards of the products we resell, providing our customers with confidence in their reliability and performance.

The Diesel/Gasoline Suction and Discharge Hose is a heavy-duty solution designed to handle both the suction and discharge of petroleum products. Its robust construction, fuel resistance, and flexibility make it suitable for demanding applications in fuel transfer, providing safety, reliability, and long-lasting performance.

10. Available Sizes

Working Pressure: 150 PSI

| ITEM CODE | I.D (mm) | I.D (inch) | O.D (mm) | W.P (bar) | W.P (psi) | B.P (bar) | B.P (psi) | WEIGHT (kg/m) | MAX LENGTH (m) |

|---|---|---|---|---|---|---|---|---|---|

| FOSD019-150 | 19 | 3/4″ | 30.8 | 10 | 150 | 30 | 450 | 0.72 | 61 |

| FOSD025-150 | 25 | 1″ | 36.8 | 10 | 150 | 30 | 450 | 0.89 | 61 |

| FOSD032-150 | 32 | 1-1/4″ | 44.8 | 10 | 150 | 30 | 450 | 1.19 | 61 |

| FOSD038-150 | 38 | 1-1/2″ | 51.4 | 10 | 150 | 30 | 450 | 1.48 | 61 |

| FOSD045-150 | 45 | 1-3/4″ | 58.4 | 10 | 150 | 30 | 450 | 1.71 | 61 |

| FOSD051-150 | 51 | 2″ | 64.4 | 10 | 150 | 30 | 450 | 1.91 | 61 |

| FOSD064-150 | 64 | 2-1/2″ | 78.4 | 10 | 150 | 30 | 450 | 2.48 | 61 |

| FOSD076-150 | 76 | 3″ | 90.8 | 10 | 150 | 30 | 450 | 3.00 | 61 |

| FOSD089-150 | 89 | 3-1/2″ | 106.2 | 10 | 150 | 30 | 450 | 4.33 | 61 |

| FOSD102-150 | 102 | 4″ | 119.2 | 10 | 150 | 30 | 450 | 4.90 | 61 |

| FOSD127-150 | 127 | 5″ | 146.2 | 10 | 150 | 30 | 450 | 6.57 | 61 |

| FOSD152-150 | 152 | 6″ | 171.6 | 10 | 150 | 30 | 450 | 7.94 | 61 |

| FOSD203-150 | 203 | 8″ | 224.8 | 10 | 150 | 30 | 450 | 12.07 | 40 |

| FOSD254-150 | 254 | 10″ | 280.8 | 10 | 150 | 30 | 450 | 19.75 | 12 |

| FOSD304-150 | 304 | 12″ | 334.2 | 10 | 150 | 30 | 450 | 27.68 | 12 |

Working Pressure: 300 PSI

| ITEM CODE | I.D (mm) | I.D (inch) | O.D (mm) | W.P (bar) | W.P (psi) | B.P (bar) | B.P (psi) | WEIGHT (kg/m) | MAX LENGTH (m) |

|---|---|---|---|---|---|---|---|---|---|

| FOSD019-300 | 19 | 3/4″ | 30.8 | 20 | 300 | 60 | 900 | 0.72 | 61 |

| FOSD025-300 | 25 | 1″ | 36.8 | 20 | 300 | 60 | 900 | 0.89 | 61 |

| FOSD032-300 | 32 | 1-1/4″ | 47.2 | 20 | 300 | 60 | 900 | 1.45 | 61 |

| FOSD038-300 | 38 | 1-1/2″ | 53.8 | 20 | 300 | 60 | 900 | 1.79 | 61 |

| FOSD045-300 | 45 | 1-3/4″ | 60.8 | 20 | 300 | 60 | 900 | 2.05 | 61 |

| FOSD051-300 | 51 | 2″ | 66.8 | 20 | 300 | 60 | 900 | 2.29 | 61 |

| FOSD064-300 | 64 | 2-1/2″ | 81.2 | 20 | 300 | 60 | 900 | 2.95 | 61 |

| FOSD076-300 | 76 | 3″ | 94 | 20 | 300 | 60 | 900 | 3.63 | 61 |

| FOSD089-300 | 89 | 3-1/2″ | 107.8 | 20 | 300 | 60 | 900 | 4.58 | 61 |

| FOSD102-300 | 102 | 4″ | 120.8 | 20 | 300 | 60 | 900 | 5.18 | 61 |

| FOSD127-300 | 127 | 5″ | 149.8 | 20 | 300 | 60 | 900 | 7.73 | 61 |

| FOSD152-300 | 152 | 6″ | 175.2 | 20 | 300 | 60 | 900 | 9.34 | 61 |

| FOSD203-300 | 203 | 8″ | 229.6 | 20 | 300 | 60 | 900 | 15.02 | 40 |

| FOSD254-300 | 254 | 10″ | 288.8 | 20 | 300 | 60 | 900 | 25.46 | 12 |

| FOSD304-300 | 304 | 12″ | 339.8 | 20 | 300 | 60 | 900 | 32.20 | 12 |

Note: Specifications, pressures, colours, etc., can be customized according to requirements.