Description

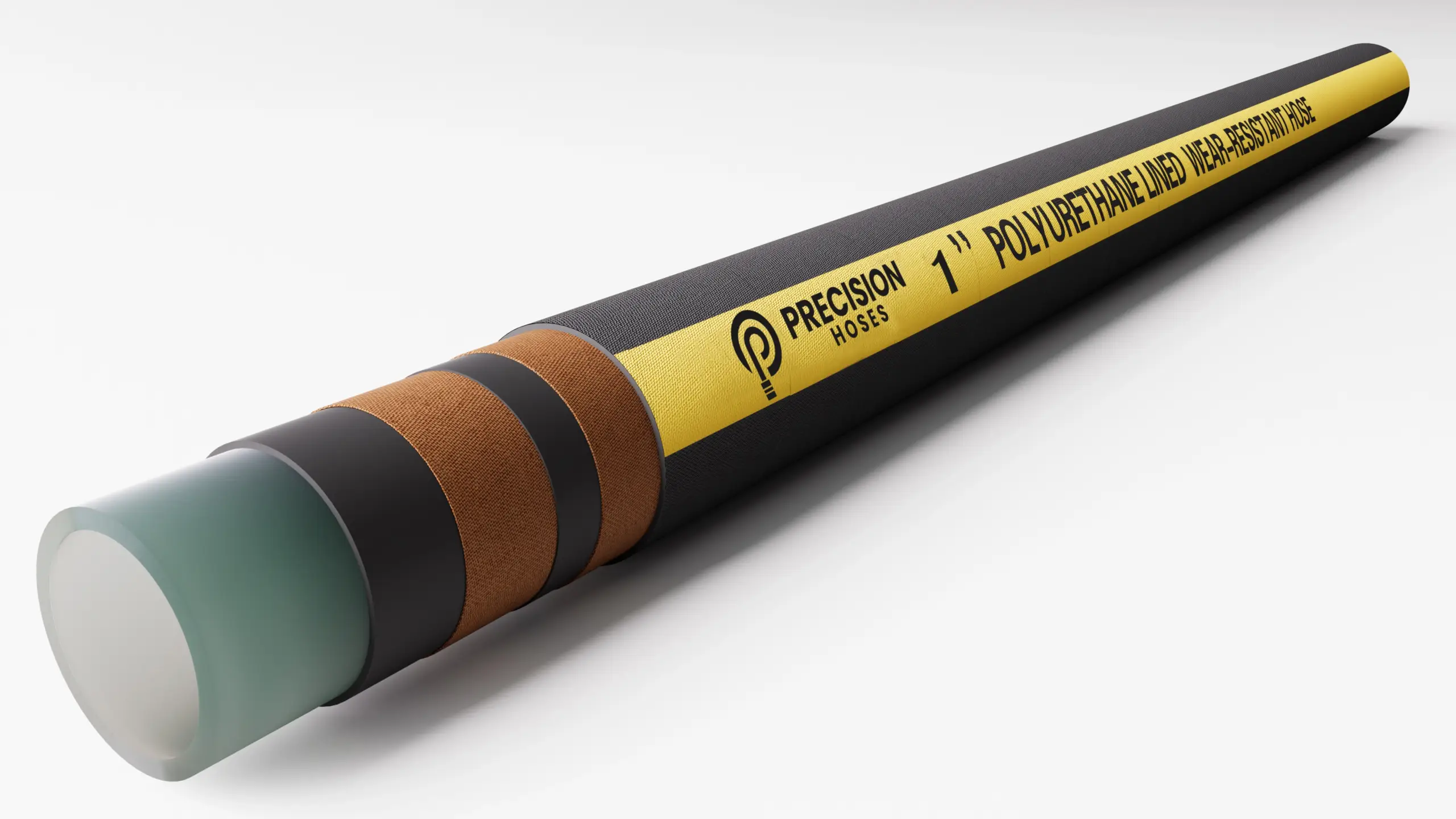

The Polyurethane Lined Wear-Resistant Hose is designed for the transfer of highly abrasive materials, offering superior wear resistance, flexibility, and durability. It is widely used in industries such as mining, construction, and material handling, where the hose must withstand harsh conditions and frequent abrasion. The polyurethane (PU) lining significantly enhances the hose’s lifespan compared to standard rubber hoses.

1. Construction

- Inner Lining: The inner lining is made from polyurethane (PU), known for its exceptional resistance to abrasion, cuts, and tears. PU lining ensures smooth material flow and significantly extends the hose’s service life, even when handling abrasive media like sand, gravel, or slurry.

- Reinforcement: The hose is reinforced with high-tensile synthetic textile plies or steel wire spirals (depending on the model), providing structural support and preventing the hose from kinking or collapsing under pressure. This reinforcement also enhances its flexibility.

- Outer Cover: The outer cover is made from weather- and abrasion-resistant synthetic rubber, which protects the hose from external wear, weathering, and impact. This tough outer layer ensures durability even in rugged working environments.

2. Standard Sizes

- Inner Diameter: Available in sizes ranging from 1 inch (25mm) to 10 inches (250mm), depending on the specific material transfer requirements.

- Length: Customizable lengths are available, with standard lengths typically ranging from 10 to 30 meters, depending on application needs.

3. Working Pressure

- The hose is designed for medium- to high-pressure applications, with working pressures typically ranging from 10 to 20 bars (145 to 290 psi), depending on the size and reinforcement type.

- Burst Pressure: The burst pressure is typically 3 to 4 times the working pressure, ensuring safety and reliability under heavy-duty conditions.

4. Abrasion Resistance

- The polyurethane lining provides superior abrasion resistance, with a wear rating much higher than standard rubber hoses. This makes the hose ideal for applications where constant exposure to abrasive materials is a concern, such as transporting sand, gravel, cement, or other rough materials.

5. Temperature Range

- The hose operates effectively in temperatures from -30°C to 80°C (-22°F to 176°F), allowing it to be used in a wide range of climates and operational environments.

6. Performance Characteristics

- High Abrasion Resistance: The polyurethane lining offers excellent resistance to abrasion, extending the hose’s service life even when used with highly abrasive materials.

- Flexibility: Despite its durable construction, the hose maintains flexibility, making it easy to handle, maneuver, and install in complex or confined spaces.

- Durability: The combination of the polyurethane lining and synthetic rubber outer cover provides long-term durability, even in the harshest working environments.

- Smooth Material Flow: The smooth inner surface of the polyurethane lining minimizes friction, ensuring consistent and efficient material flow while reducing the risk of blockages.

7. Applications

- Ideal for material handling in industries such as mining, quarrying, construction, and cement plants, where the transfer of highly abrasive materials like sand, gravel, and cement is required.

- Suitable for slurry transport, gravel pits, shotcrete delivery, and dredging operations, where abrasion resistance is a key requirement.

- Used in applications involving dry bulk material transfer, pneumatic conveying, and hopper suction and discharge.

8. End Fittings

- The hose can be fitted with various types of flanged couplings, camlock fittings, or quick-connect couplings, depending on the operational needs. These fittings are typically made from abrasion-resistant metals to complement the hose’s durability and provide secure, leak-proof connections.

9. Certifications

The manufacturer of the products supplied by Precision Hoses Pty Ltd is certified under the ISO 9001:2008 Quality Management System, ensuring a consistent commitment to quality. Additionally, the manufacturer’s products have achieved key industry certifications, including the BV Certificate, CE Certificate, ECM Certificate, and CCS Certificate, awarded in 2010. These certifications highlight the exceptional standards of the products we resell, providing our customers with confidence in their reliability and performance.

The Polyurethane Lined Wear-Resistant Hose is a high-performance hose designed for applications involving abrasive materials. With its exceptional abrasion resistance, flexibility, and durability, it offers reliable, long-lasting service in industries that require frequent material transfer under demanding conditions.

10. Available Size

| Item Code | I.D | O.D | Working Pressure | Burst Pressure | Max Length | |||

|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | bar | psi | bar | psi | m | |

| PWD019-174 | 19 | 3/4″ | 38 | 20 | 300 | 60 | 900 | 61 |

| PWD025-174 | 25 | 1″ | 44 | 20 | 300 | 60 | 900 | 61 |

Note: Custom sizes and lengths are available upon request to meet your specific needs.