Description

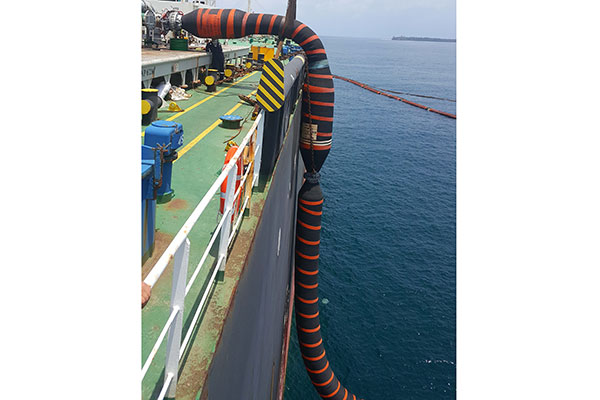

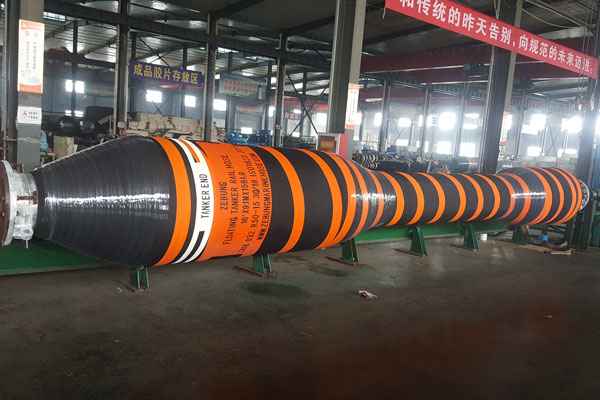

The Tanker Rail Floating Hose is a high-performance marine hose designed for connecting pipeline end manifolds (PLEMs) to vessels in Floating Production Storage Offloading (FPSO) systems. Engineered to deliver efficient and safe fluid transfer, this hose ensures durability and reliability in offshore oil production and marine operations. The hose is equipped with advanced features, including leak detection systems and buoyancy capabilities, making it ideal for demanding environments.

1. Construction

- Inner Tube: Made from high-quality oil-resistant synthetic rubber, the inner liner is specifically designed to handle crude oil, refined petroleum products, and liquid hydrocarbons. Its smooth surface minimizes flow resistance, ensuring optimal fluid transfer and preventing contamination.

- Reinforcement: The hose is reinforced with multiple layers of high-tensile synthetic fabrics and a helix steel wire structure. This combination provides exceptional strength, structural integrity, and resistance to kinking under internal pressure and dynamic loads.

- Outer Cover: Constructed from abrasion-resistant synthetic rubber (NBR + CR), the outer cover is highly resistant to wear, oil spills, seawater, UV radiation, and adverse weather conditions, ensuring durability in harsh marine environments.

2. Standard Sizes

- Inner Diameter: Available in standard sizes ranging from 6 inches (150mm) to 16 inches (400mm) to suit various transfer capacities.

- Length: Standard lengths range from 10 meters to 20 meters, with customizable lengths available based on specific project requirements.

3. Working Pressure

The Tanker Rail Floating Hose is rated for high-pressure fluid transfer with a working pressure of up to 21 bars (304 psi). Its robust construction ensures reliable performance in demanding offshore applications.

4. Reserve Buoyancy

- The hose is designed with a minimum reserve buoyancy of 20% (or as specified). This ensures that the hose remains afloat during operations, enabling safe handling and continuous functionality in marine conditions.

5. Leak Detection System

The Tanker Rail Floating Hose features a highly reliable and efficient leak detection and indication system.

- How It Works: The system detects damage to the main carcass, immediately triggering a response to indicate the leak.

- Benefits: This quick response allows operators to identify and remove the damaged hose promptly, minimizing operational downtime, reducing economic losses, and preventing environmental hazards caused by leaks.

6. Performance Characteristics

- Tensile Strength: The multiple layers of reinforcement ensure the hose can withstand high tensile loads encountered during offshore transfer and vessel movements.

- Flexibility: Despite its robust construction, the hose maintains flexibility to adapt to vessel movements, waves, and dynamic offshore environments.

- Abrasion Resistance: The rugged outer cover offers excellent resistance to physical abrasion, seawater, and rough handling, ensuring a long service life even in challenging marine operations.

- Leak Protection: The integrated leak detection system provides an added layer of safety to protect both the operation and the marine environment.

7. Applications

- Designed for connecting pipeline end manifolds (PLEMs) to tankers and FPSO units.

- Ideal for ship-to-ship and ship-to-shore fluid transfer of crude oil, refined petroleum products, and liquid hydrocarbons.

- Used in offshore oil production systems where safe and efficient petroleum transfer is critical.

- Suitable for floating production and storage systems, ensuring reliable operations under dynamic marine conditions.

8. Safety Features

- Leak Detection System: Prevents spills and environmental damage by providing immediate detection of leaks.

- Reserve Buoyancy: Keeps the hose afloat during operations, ensuring operational safety and reducing risks in rough sea conditions.

- Corrosion Resistance: The hose’s construction materials protect against corrosion from seawater and oil exposure, ensuring safety and extended service life.

9. Certifications

The manufacturer of the products supplied by Precision Hoses Pty Ltd is certified under the ISO 9001:2008 Quality Management System, ensuring a consistent commitment to quality. Additionally, the manufacturer’s products have achieved key industry certifications, including the BV Certificate, CE Certificate, ECM Certificate, and CCS Certificate, awarded in 2010. These certifications highlight the exceptional standards of the products we resell, providing our customers with confidence in their reliability and performance.

10. Technical parameters:

| I.D | Weight (kg) | O.D (mm) | Min. B.R (m) | ||||

|---|---|---|---|---|---|---|---|

| mm | 9.1m | 10.7m | 12.2m | A | B | C | (m/ft) |

| 150(6″) | 524 | 576 | 628 | 500 | 290 | 440 | 0.6(2.0′) |

| 200(8″) | 726 | 817 | 908 | 560 | 350 | 530 | 0.8(2.7′) |

| 250(10″) | 931 | 1037 | 1143 | 690 | 420 | 530 | 1.0(3.3′) |

| 300(12″) | 1091 | 1225 | 1359 | 810 | 490 | 640 | 1.2(4.0′) |

| 400(16″) | 1650 | 1839 | 2028 | 1000 | 580 | 840 | 1.6(5.3′) |

| 500(20″) | 2200 | 2550 | 2800 | 1100 | 720 | 1000 | 2.0(6.7′) |

Note: Specifications, pressures, colours, etc., can be customized according to requirements.