Description

The Water Suction and Discharge Hose with Flange is a robust, heavy-duty hose specifically designed for water transfer applications requiring secure, high-performance connections. Equipped with integral flanges on both ends, this hose is ideal for quick installation and connection to pipes, pumps, and other water handling equipment in industries such as construction, agriculture, mining, and marine. The flanged ends provide a tight, leak-free connection for maximum efficiency and reliability in both suction and discharge operations.

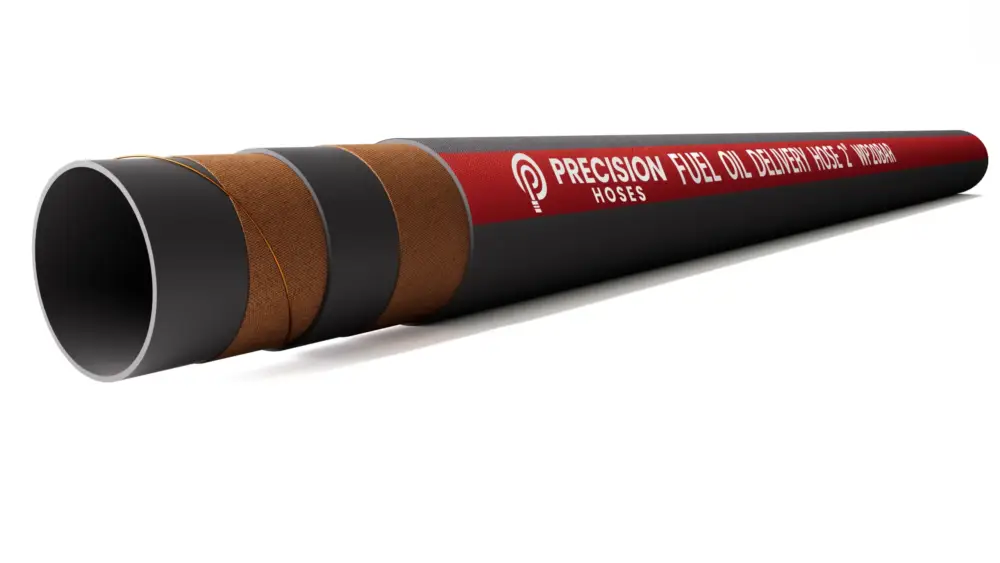

1. Construction

- Inner Tube: Made from high-grade, smooth synthetic rubber, the inner tube is designed to handle water and mild chemicals while providing a consistent and smooth flow. It is highly resistant to wear and abrasion, ensuring durability.

- Reinforcement: The hose is reinforced with synthetic textile plies and/or a steel wire helix, allowing it to handle high-pressure suction and discharge applications. The wire helix prevents kinking and crushing while maintaining flexibility.

- Outer Cover: The outer cover is made from abrasion-resistant synthetic rubber, designed to withstand harsh environmental conditions, such as abrasion, weather, and ozone exposure. This cover ensures long-lasting performance in tough outdoor applications.

2. Flange Connection

- Integral Flanges: The hose comes with integral flanges on both ends. These are typically made from steel or galvanized metal and are permanently attached to the hose body for a secure, reliable connection. The flanges are usually drilled to standard bolt patterns (e.g., ANSI, DIN, or BS standards) for compatibility with various pipe systems.

- Bolt Holes: Pre-drilled bolt holes allow for easy attachment to flanged pipes, pumps, or other equipment, ensuring a leak-free and tight connection during water transfer.

- Gaskets: Often supplied with rubber gaskets to ensure a tight seal between the hose and the connected equipment, preventing leakage during high-pressure operations.

3. Standard Sizes

- Inner Diameter: Typically available in sizes ranging from 2 inches (50mm) to 12 inches (300mm), depending on the application and volume of water being handled.

- Length: Available in standard lengths of 10 meters to 20 meters, with custom lengths provided upon request.

4. Working Pressure

- The hose is designed for medium to high-pressure applications, with typical working pressures ranging from 10 to 20 bars (145 to 290 psi), depending on the hose size and construction.

- The flanged ends allow for safe, high-pressure connections to pumps and pipelines without the risk of hose blow-off.

5. Vacuum Rating

- The hose is capable of full vacuum service, with a vacuum rating of 29 inches of mercury (Hg), making it ideal for water suction applications, including dewatering, drainage, and flood control.

6. Temperature Range

- This hose operates effectively in a temperature range of -20°C to 80°C (-4°F to 176°F), allowing for use in various environments and climates.

7. Performance Characteristics

- Flanged Ends for Secure Connections: The integral flanges ensure a safe, reliable, and quick connection to pumps, valves, and pipes, making it ideal for applications requiring frequent hose removal or replacement.

- Abrasion Resistance: The outer cover is designed to withstand rough surfaces, weather conditions, and prolonged use, ensuring a long lifespan in rugged environments.

- Kink and Crush Resistance: The steel wire helix reinforcement ensures the hose maintains its shape during suction operations, preventing kinking or collapsing under negative pressure.

- Chemical Resistance: The inner tube can handle water mixed with mild chemicals, ensuring versatility in various water transfer tasks.

8. Applications

- Suitable for industrial water suction and discharge tasks in agriculture, construction, mining, and marine industries.

- Commonly used for pumping operations involving water intake and discharge, such as dewatering, flood control, irrigation, and drainage systems.

- Ideal for use in portable pump setups, where hoses need to be quickly and securely connected to pumps, tanks, or pipelines.

- Widely used in marine environments for water handling on docks, ships, or for bilge pump systems.

9. Certifications

The manufacturer of the products supplied by Precision Hoses Pty Ltd is certified under the ISO 9001:2008 Quality Management System, ensuring a consistent commitment to quality. Additionally, the manufacturer’s products have achieved key industry certifications, including the BV Certificate, CE Certificate, ECM Certificate, and CCS Certificate, awarded in 2010. These certifications highlight the exceptional standards of the products we resell, providing our customers with confidence in their reliability and performance.

The Water Suction and Discharge Hose with Flange is designed to provide reliable, high-performance water transfer with secure, easy-to-use flanged connections. Its robust construction and reinforced design make it suitable for tough industrial applications, providing the flexibility and durability needed for efficient water handling. Ideal for use in demanding environments, this hose ensures efficient and safe water transfer in both suction and discharge tasks.